Aubrey's 1962 Chevrolet Belair sport coupe. 409 409HP, 4 speed, Prepared for NHRA D Stock

Division 6 / Number 6409

In response to my application to NHRA, the Tech Department / HP Factoring Committee has approved my request for a horsepower reduction for classification purposes... effective December 15, 2003, the 409 HP 409 was re-factored to 395 horsepower.

This photo, taken in June, 1999, after an outing at Calgary's Race City Speedway.

A photo shoot on August 25, 2005. Most of these pictures open to 1024 X 768 pixels.

Note the condition of the factory paint under the hood. Nothing on this car has been repainted ( except the engine ! ).

The 1965 409 passenger car block, 3857656 , just back from the machine shop. On the right is a "clone" of the GM Z11 / over the counter racing oil pan which I copied from specs of an original..... The originals being priced beyond the stratosphere ! Capacity is up from 5 litres, to 7 litres. Installed to the factory windage tray studs, is a new Milodon full screen BBC windage tray... There is also a baffle to prevent oil splashing up the rear of the pan during launch.

Above right, Chevy valve covers repainted, and were chosen to be run without the steel wire looms so to avoid the potential for "cross firing" between the plug wires.

And HERE THEY ARE !......... After much effort, both with Ross Racing Pistons, AND NHRA......

Forged 11:1 racing pistons with the NHRA approval for Stock Eliminator class ( Approval obtained, July, 2003 ). This is the first and only NHRA accepted piston for the 409 Chevy engine for Stock Class racing. Available From Ross Racing Pistons, PART NUMBER 77563.

Centre, a typical performance 409 camshaft compared to the brand new NHRA legal Stock race camshaft which was machined to my specs by Competition Cams in Tennessee. Note the EXTREME lift rate on the lobes.

On the far right are a couple photos of the 409 high performance cylinder head valve arrangement.

Schubeck light weight composite mechanical lifters. Total Seal "dykes" compression rings with low tension oil ring. These are installed in factory 5/64" ring grooves, using spacers also available from Total Seal.

On the right, new Crane "Nitro-Carb" 1.7 ratio rockers for 7/16" stud... made right here in Canada !

Here is my brand new CSI electric aluminum water pump. Chosen for light weight and horsepower savings. The pair of adaptors are not available commercially. We made these ones in house, using aluminum plate and square tubing, then welding together. These will be "buffed up" a bit before final assembly ! The unit now bolts on the front of a 348 or 409 block... just like the original cast iron part. On the far right, my new 7" ATI 3 piece ALUMINUM crankshaft dampener.

Here's the block, detailed and prepped. Piston and rod assemblies ready for installation.... and progress on the short block ! On the right is the crank scraper which I fabricated for the engine.

Here's the assembled engine just about ready for installation. Will detail the intake and add a few accessories first.

The engine installed, and hooking up accessories for the cam break in and tuning on May 11, 2004. Hot valve adjustment... And after the test run, hood installed, see what she looks like ! We removed the engine and took it to the dyno at Lee Brother's machine shop in Red Dear, Alberta. LOOK FOR THE

THE 409 RACE HEADERS ! that I built for the car...

Shown here is the chassis that was used to build the headers. The fit is exactly symmetrical !

These were built using 3/8" flanges and 16 Hooker "J" bends. Tubing is 2" for first 8", stepped into 2 1/8", then into 3 1/2" collectors.

The headers after approximately 6-7 inches was taken out of the primary tubing length. This helped raise the torque curve a little bit, and a few extra horsepower on the top end. Primary tubing length is now 32"-36".

Brand new Jerico drag race 4 speed transmission ! 2.83 1st gear, roller tail housing for reduced friction uses special machined billet driveshaft yoke. Transmission is the same length and mounting as the BW Super T10 that I have used for years ( shown with the Super Shifter attached ).

Here are the rear end upgrades. Fully webbed housing with second ( left ) upper control arm. Differential bearing cap girdles. New 30 spline Moser axles... compared to original 17 spline. And just in, my brand new custom made "4 series" spool for the 30 spline axles ! And the rear end pumpkin ready for installation. On the right, my rear lower control arms which I just boxed ( Aug, 2005 ), and completely re-bushed suspension with "Energy Suspension" polyurethane bushings.

Here is a view of the original floor showing the factory Corona Cream paint as applied by GM of Canada. Much controversy exists regarding how the floor should be painted... this is how it was done ! The brown over spray you see is an adhesive that was used to secure the carpet under-lay. The trunk is completely rust free original..

Just located the photos of the roll bar installation ! Chris Alston 8 point kit. We did the fitting, welding and installation here in our shop.

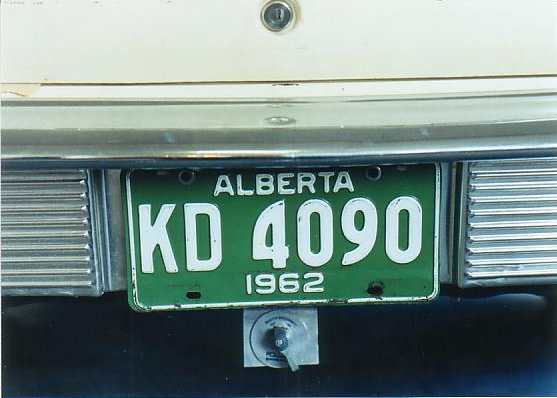

Yes, these ARE the license plates registered to this car ! Note the battery power shut-off.

First road test with the slicks and roll cage installed... July 31, 2004 !

Here is the engine compartment... photo taken July 31, 2004. I received approval from NHRA on the Edelbrock PN 1405 600 CFM AFB carburetors as accepted for Stock Eliminator and Super Stock.

This page updated February 21 , 2019.

E MAIL me about this car !

To go to main page just click: http://www.bruneauperformance.ca

Copyright © 2003-2019 A Bruneau Performance Ent. All Rights Reserved World Wide.